Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

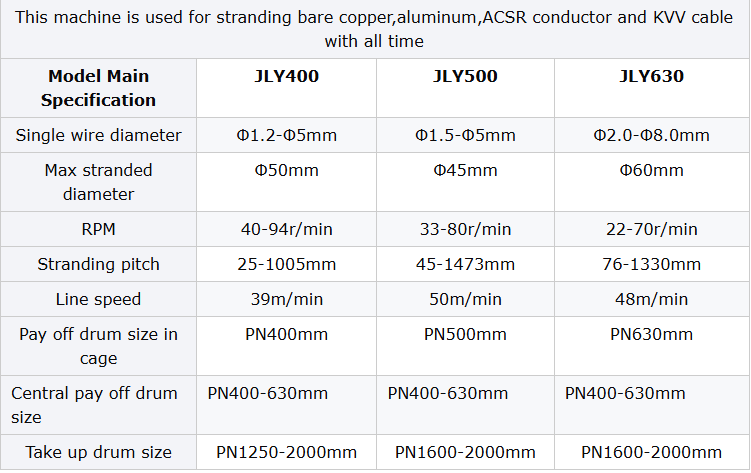

JLY300/6+12+18+24 Planetary Stranding machine

The JLY300/6+12+18+24 Planetary Stranding Machine is a high-performance solution for manufacturing control cables, power cables, and cross-linked polyethylene (XLPE) cables. Engineered with advanced tension control, robust structural design, and complete safety measures, this machine ensures stable, efficient, and high-quality cable stranding. Its user-friendly interface and low-maintenance design make it an ideal choice for professional cable production environments.

Product Features

Reliable Mechanical Tension Control

Uses adjustable mechanical friction control to precisely manage pay-off tension, accommodating a variety of cable specifications and production demands.

High-Rigidity Cradle Design with Ground Axis Linkage

The cradle-type twisting body, reinforced by a ground axis linkage system, enhances structural stability and ensures precise pitch control during high-speed operations.

Advanced Star-Shaped Twisting Structure

Incorporates a star-shaped gear system for full cable twist and anti-twist technology, resulting in uniform, high-quality stranding.

Comprehensive Safety and Lubrication Systems

Equipped with centrifugal break protection and vertical protective covers for each strand, plus a separate motor-driven gear pump for reliable and continuous gear lubrication.

Operator-Friendly and Low Maintenance

Designed for ease of use, with accessible components for quick upkeep, minimizing downtime and supporting continuous, efficient production cycles.

Technical Specifications

Product Advantages

Superior Stranding Performance

Delivers consistent cable roundness and twist precision, thanks to its advanced gear system and anti-twist design.

Enhanced Operational Safety

Integrated safety covers and break protection mechanisms help prevent accidents, ensuring secure and reliable operation.

Built for Speed and Efficiency

High-rigidity structure supports fast rotation and improved productivity without compromising product quality.

Reduced Maintenance Costs

Simplified access and automated lubrication reduce the need for frequent manual servicing, lowering long-term maintenance expenses.

Adaptable to Varied Cable Types

Suitable for laying up control cables, power cables, and XLPE cables, providing versatile performance across different production lines.

Order Information

- Lead Time: 30-180 days

- Payment Methods: T/T, L/C

- Minimum Order Quantity: 1 unit

- Customization: Available

- OEM & ODM: Supported

- After-sales Service: 24/7 online support, on-site visits possible

- Warranty: 1 year

- Workshop Facilities: Specialized production, welding, and assembly workshops

- Quality Control: Experienced QC engineers (15+ years)

- Logistics: Sea freight, plastic film packaging, wooden boxes at extra cost